Facilities

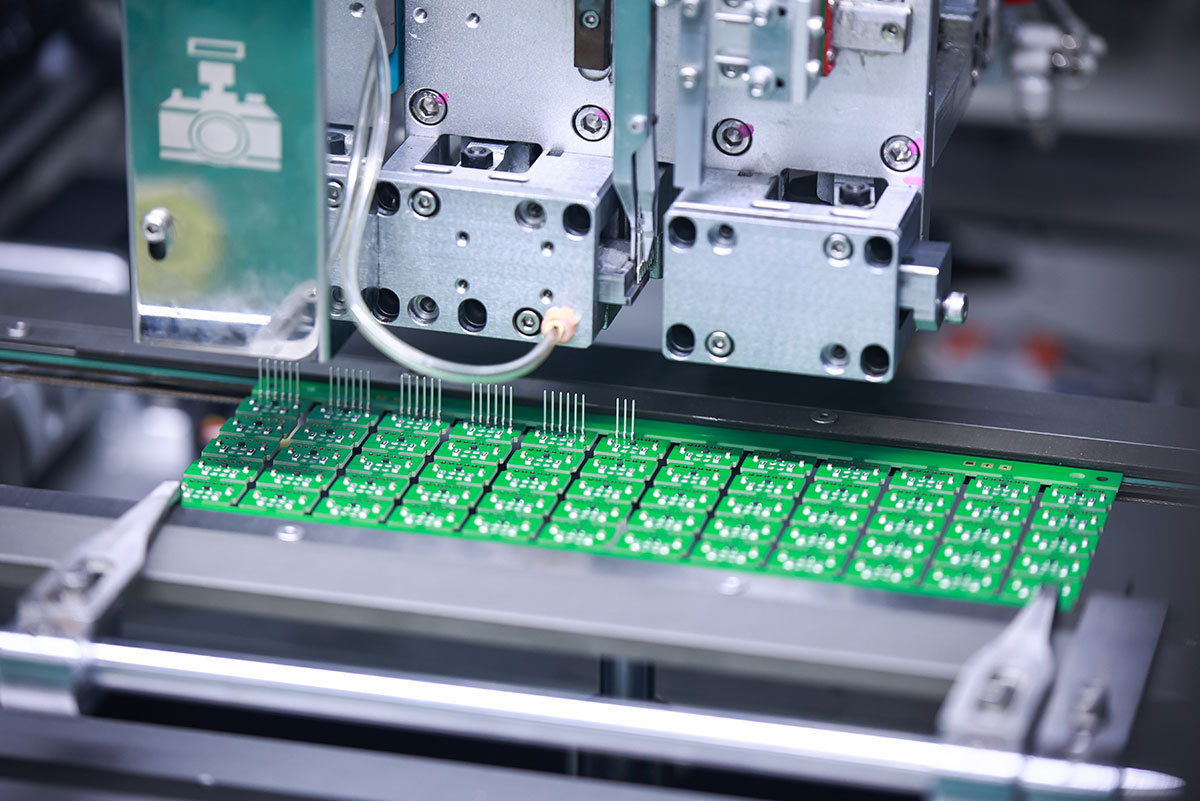

Surface Mount Technology

With four fully equipped SMT (Surface Mount Technology) lines, including two high-speed lines, we have the in-house capability to assemble our own printed circuit boards (PCBs). This vertical integration allows us to maintain full control over production quality, ensure faster turnaround times, and enhance flexibility in meeting specific customer requirements. By managing PCB assembly internally, we minimize dependency on third parties and uphold strict quality assurance standards at every stage of the manufacturing process.

PCBA Wave Soldering Facilities

In-house wave soldering capabilities allow us to efficiently handle through-hole PCB assembly with high reliability and consistency. By managing the wave soldering process internally, we ensure superior solder joint integrity, optimized thermal profiles, and reduced defect rates. This level of control enables us to meet rigorous quality standards, improve production efficiency, and deliver dependable performance across all assembled boards.

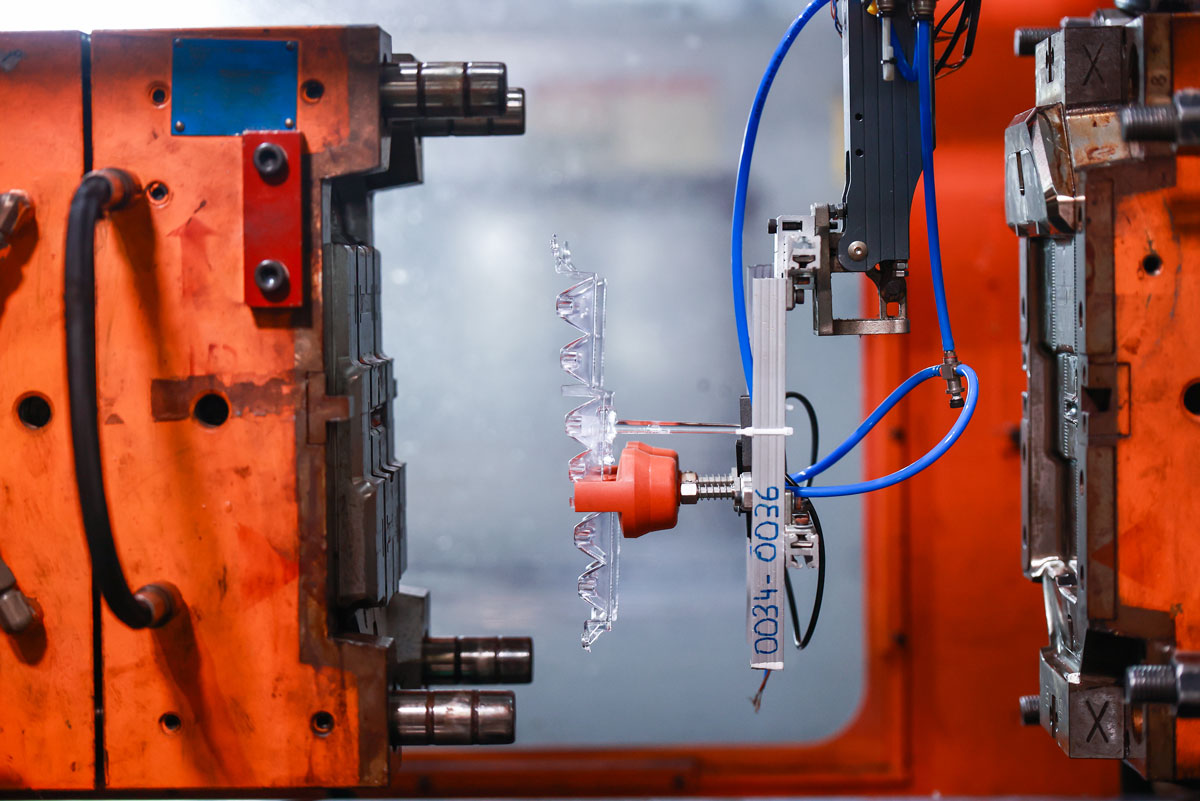

Plastic Injection

Our production capabilities include 20 horizontal injection molding machines ranging from 40 to 710 Tonnage. This wide tonnage range enables us to manufacture a broad spectrum of high-quality custom plastic parts, from small precision components to larger structural parts.

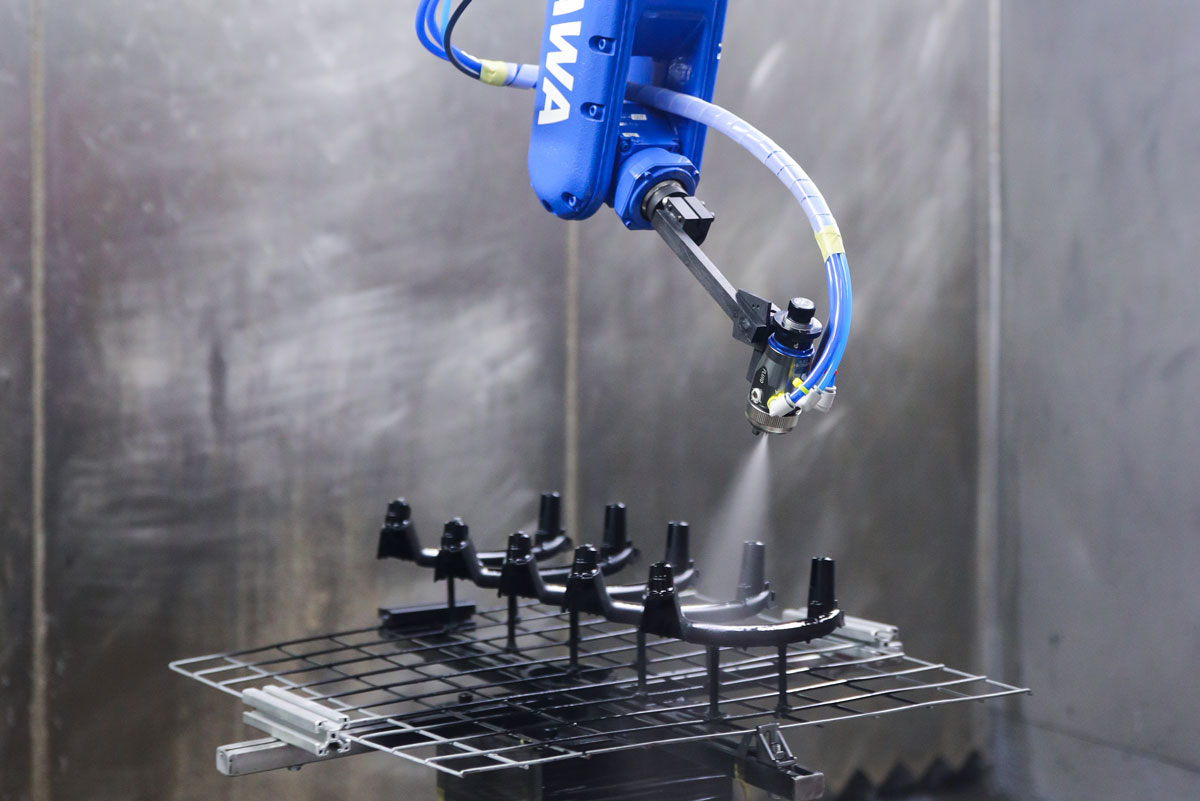

Spray Painting

MCE’s facility is equipped with three advanced spraying lines, including two six-axis robotic spray systems integrated with a Rapid Colour Change (RCC) system. These six-axis robots provide precise, consistent application across complex geometries, ideal for automotive components requiring high-quality finishes.

Vacuum Metalizing

We utilize a 2-Chamber Vacuum Metalizing Machine in-house to perform high-precision metalization of lamp reflectors. This advanced system allows us to deposit reflective coatings—typically aluminum—onto plastic or polymer reflector surfaces under vacuum conditions, ensuring consistent surface quality, enhanced light reflection, and long-term durability.

Auto Pressfit Machine

Our use of advanced auto press-fit machines ensures high-precision alignment and consistent insertion performance across all assemblies. This technology enhances design flexibility while enabling more cost-effective and scalable manufacturing solutions.

Testing Facilities

Environmental Testing

To guarantee our products perform optimally under various environmental conditions, we conduct extensive environmental testing. This includes assessments for temperature extremes, humidity, and exposure to corrosive elements, ensuring resilience and longevity in diverse operating environments.

Durability Testing

Durability testing is integral to our quality assurance process. By simulating real-world usage scenarios, we assess the lifespan and robustness of our products, making certain they withstand the demands of everyday use and maintain performance over time.

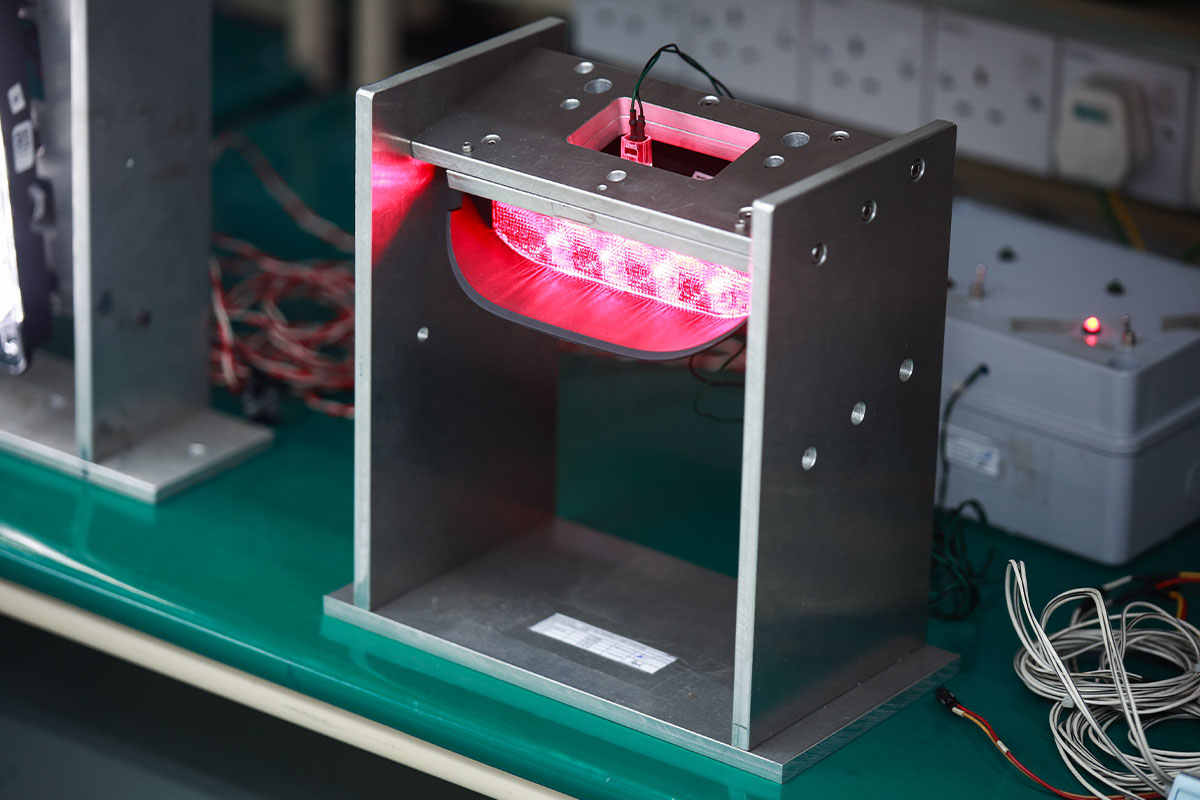

Photometric Testing

Our photometric testing capabilities allow us to evaluate the lighting performance of automotive components. By measuring parameters such as luminosity and light distribution, we ensure our lighting products provide optimal visibility and comply with regulatory standards.

Quality Control

Coordinate Measuring Machine (CMM)

Equipped with a high-precision Coordinate Measuring Machine (CMM), we ensure dimensional accuracy and compliance with tight engineering tolerances across our manufactured components. The CMM enables us to perform detailed 3D measurements and geometric inspections with micron-level precision, supporting both in-process quality control and final product validation. This capability enhances our ability to maintain strict quality assurance standards and deliver consistent, high-performance parts to our customers.

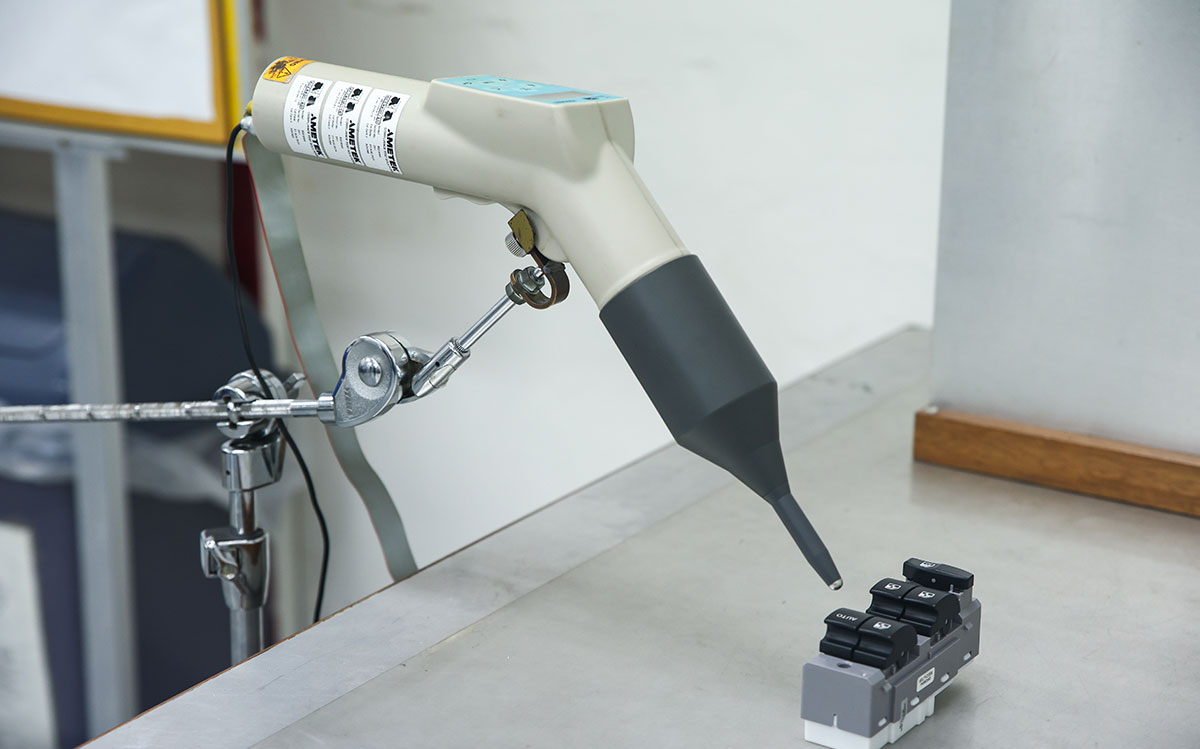

IP Panel Switch Tester

Regulator Auto QC Tester

We develop fully customized End-of-Line (EOL) testing systems in accordance with OEM specifications to verify the functional integrity of each unit. These systems are designed to detect electrical, mechanical, and performance-related anomalies, ensuring zero-defect outflow to the customer.